Facilities

Continuous-Flow High-Pressure and High-Temperature Spray Chamber

A high-temperature high-pressure spray chamber is under construction and will stand as the flagship research facility at the SPhERe Lab. The optically-accessible chamber, illustrated schematically at left, will allow for a wide range of laser diagnostics to be employed for probing fuel spray physics and chemistry in simulated gasoline and diesel engine environments. The chamber offers a highly-controlled, flexible combustion environment ideal for fundamental investigations and/or model development and validation.

Unique capabilities of the facility include:

- Highly-controlled extreme pressure and temperature conditions. Operating pressures from 5 – 100 bar, temperatures from 300 – 1000 K. These ranges cover current and future engine operating condition trends, including highly-boosted multi-injection conditions.

- Multi-view, 90-degree optical access. Enables the application of a multitude of imaging and laser-based diagnostics, including: time-resolved imaging of liquid and vapor-phase fuel dispersion, time-resolved imaging of ignition and combustion, planar laser-induced fluorescence (PLIF) of key combustion species, and laser-induced incandescence (LII) of soot.

- Technology-flexible. Fuel-injection system is capable of operating gasoline and diesel fuel injectors. Our system can provide fuel-injection pressures of up to 4100 bar.

- Fuel-flexible. Fuel-injection system is designed for compatibility with non-traditional fuels such as oxygenates and fuels with low lubricity.

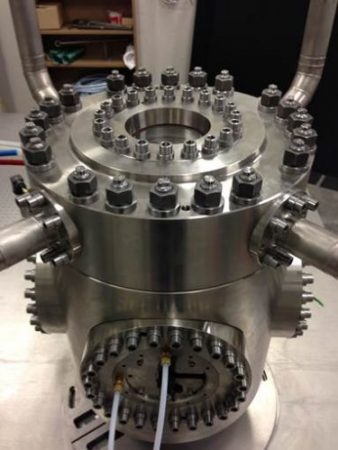

Ultra-High-Pressure Liquid Fuel-Injection System

The liquid fuel-injection system, pictured on the right, was designed to facilitate future fuel-flexible and high-pressure injection strategies. This system features an air-operated L300-2 pump, 1-gallon reservoir, and nitrogen purge circuit.

Unique capabilities of the facility include:

- Ultra-high pressurizing capability, 650 – 4100 bar.

- Controllable fuel temperature, silicone-oil chiller/heater to control injector body temperature, 0-200 deg. C

- Fuel-flexible, compatible with non-traditional fuels like oxygenates and low-lubricity fuels.